The Charger Blog

University Hosts Immersive Satellite Imagery Workshop

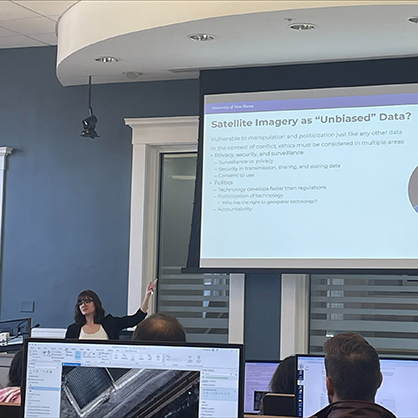

Satellite imagery is becoming an increasingly valuable tool in many fields, and several Chargers recently had the opportunity to learn how to apply it to do everything from tracking the conflict in Ukraine to determining whether images had been tampered with.